Artdeshine’s SEM Imaging Confirms Increased Coating Thickness

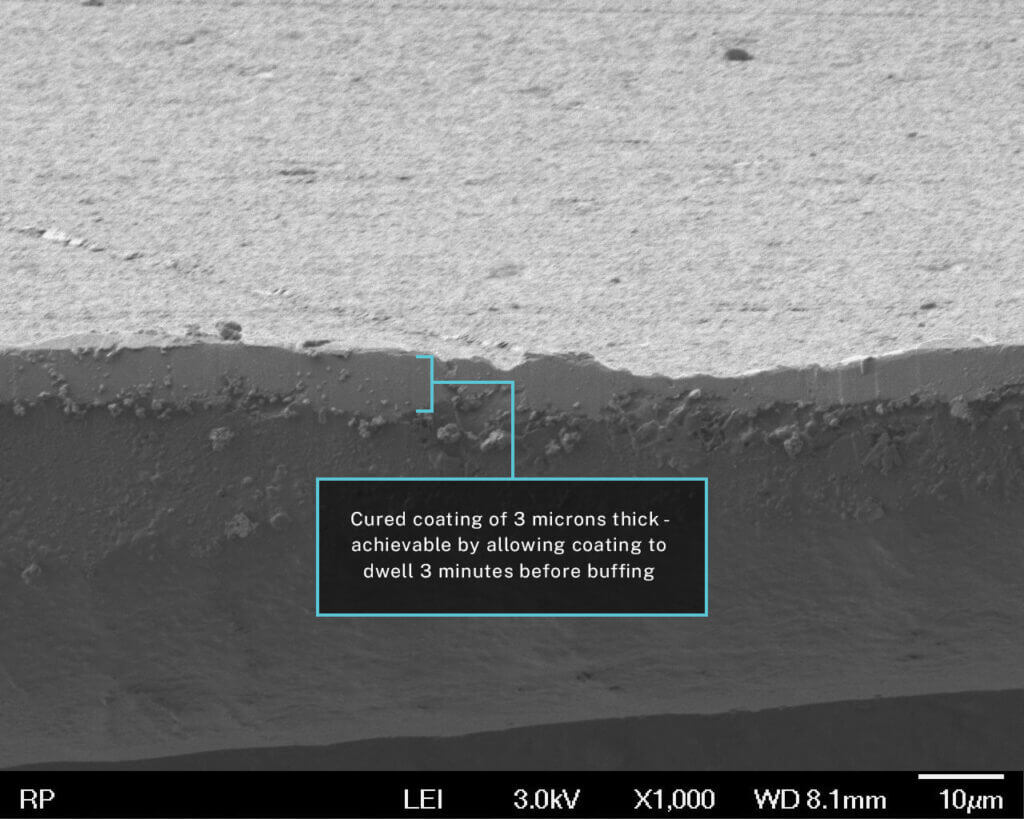

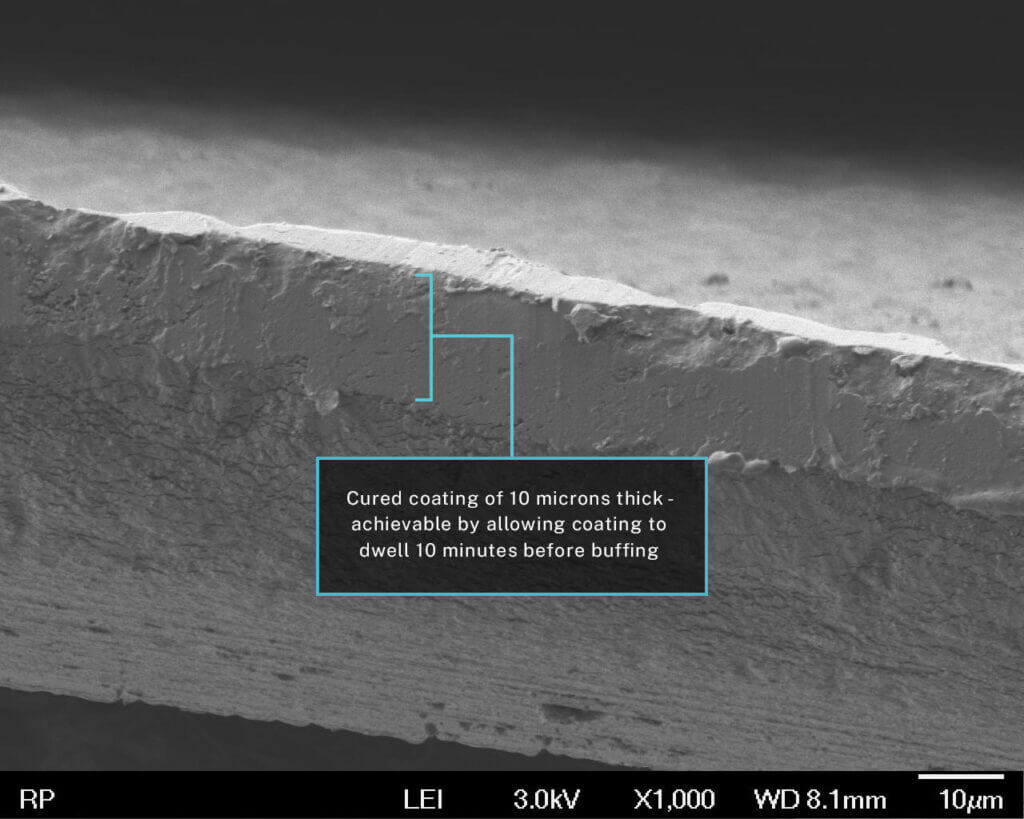

Artdeshine, a leading manufacturer of professional-grade automotive coatings and detailing products, has announced a recent discovery that could revolutionize the application process of their coatings. After conducting extensive testing, it has been found that increasing the time between coating application and buffing can result in an increased coating thickness without affecting the user-friendly attributes of coating removal.

Regional leaders of Artdeshine began testing this theory, and the Artdeshine Singapore team conducted scanning electron microscope (SEM) imaging to confirm the findings. The results have indicated that allowing an applied Artdeshine coating to cure for up to 10 minutes will have a substantially positive impact on the cured coating thickness, with an overall coating thickness of up to 10 microns achievable with the updated application instructions. It’s important that all installers and users of Artdeshine products are aware that even though it’s possible to achieve a thickness of up to 10 microns, the overall coating thickness achieved by an end user will be determined by how much product they are using. For example, our tests indicate that a user would need to use upwards of 200-300ml of coating for it to be possible in achieving this level of thickness. Essentially for every m2 of exterior surface coated, we need to use 10ml of Nano Graphene Coating. Regardless, we still see substantial thickness improvements to our products by increasing the dwell time, even with normal product usage.

While this discovery will not be increasing any durability claims, it is expected to improve the overall performance and resilience of the coating. Having a thicker coating in theory will help to reduce erosion from wiping and washing, which is excellent news for car enthusiasts and professionals alike who want to ensure their vehicle’s finish is protected.

The reasoning behind this new technique is that when a coating starts to dry, less product is absorbed by the microfiber towel, allowing more product to stay on the surface and resulting in a thicker coating. By extending the curing time, users will be able to achieve a thicker coating without having to sacrifice any of the user-friendly attributes of coating removal.

Artdeshine is committed to providing the best possible products and experience for both customers and installers. The company has recommended that each installer and region review the current installation instructions for each coating to ensure they are following the most up-to-date guidance. Artdeshine would like to thank their regional partners and installers for their dedication and hard work in striving to learn and improve their craft, ultimately leading to this exciting discovery.

Artdeshine Forever!